Basic Machine Tending Application Programming

Basic Machine Tending Application Programming

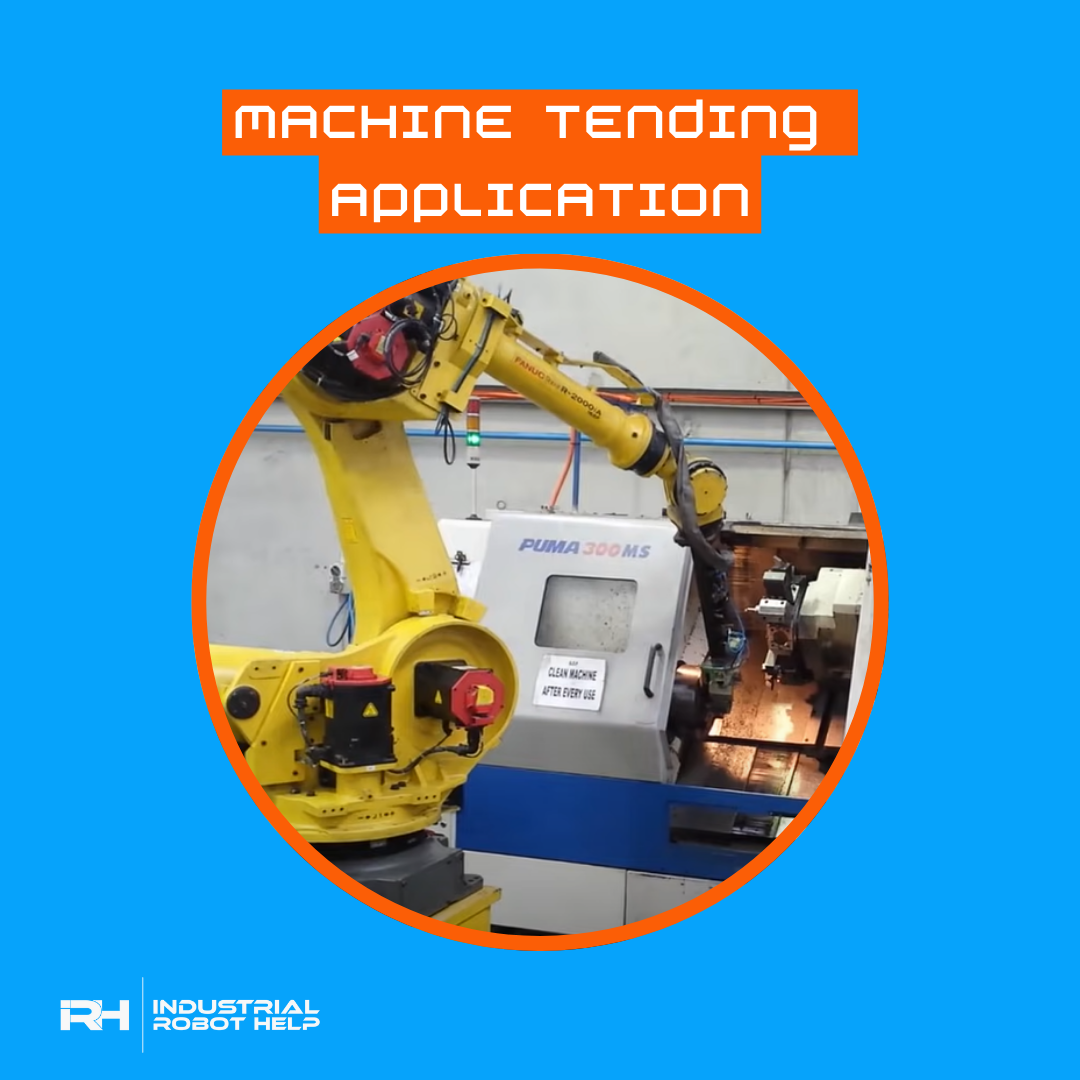

Maximize uptime and throughput with intelligent machine tending automation.

Keep your CNC machines, injection molding presses, die casting equipment, and laser cutters running at peak capacity. Our engineers develop reliable machine tending programs that coordinate seamlessly with your production equipment—reducing cycle times, minimizing part handling errors, and freeing operators for higher-value tasks.

Service Package Includes

Application Discovery Session

We review your robot system, machine tool interfaces, part specifications, cycle time requirements, door interlocks, and safety protocols to design a coordinated automation solution.

25 Hours of Expert Programming

Dedicated engineering time to develop your machine tending application, including load/unload sequences, machine I/O handshaking, part orientation logic, and error recovery routines.

Custom Working Code

Production-ready programming tailored to your specific equipment and parts. Optimized for safe, efficient material flow and maximum machine utilization.

Pre-Delivery Testing & Debug

Basic debugging and code validation before shipment to ensure your program is ready for deployment.

Remote Service Package: This offering includes remote programming and support. On-site installation, commissioning, and extended debugging services are available separately. Contact us for a custom quote tailored to your needs.