Advanced HMI System for igus Gantry Robots

Advanced HMI System for igus Gantry Robots

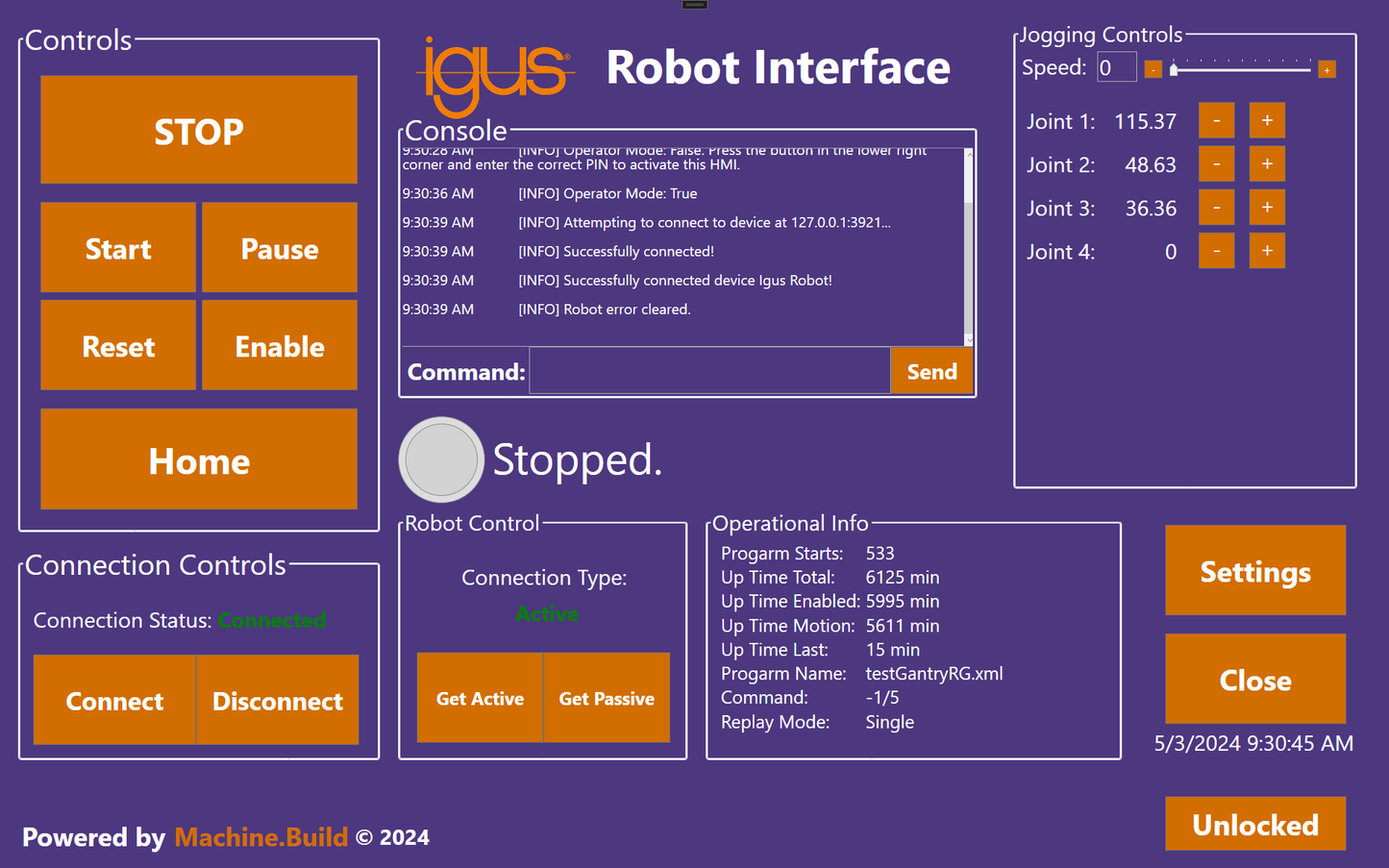

Specialized operator interface engineered for igus drylin gantry automation systems.

Take full control of your igus gantry robot with a purpose-built HMI system designed specifically for linear motion applications. This ready-to-deploy solution integrates seamlessly with igus robot control software, featuring gantry-specific functions including home position management, axis referencing, and customizable operator controls—all wrapped in an industrial-grade touchscreen interface.

Key Features

Gantry-Optimized Controls

Purpose-built for linear robot systems with specialized functions including home position setup, multi-axis referencing sequences, and coordinated gantry motion control. No programming required—designed specifically for igus drylin gantry applications.

Customizable Operator Layer

Flexible interface that adapts to your production needs. Configure application-specific controls, create custom buttons for repeated tasks, and tailor the operator experience to match your workflow.

Industrial-Grade Durability

Ruggedized 10" Windows tablet with IP-68 rating withstands dust, moisture, and harsh factory conditions. Built to deliver reliable performance in demanding manufacturing environments.

Crystal-Clear Display

1920x1200 high-resolution touchscreen with intuitive GUI provides clear visibility of multi-axis positions, system status, and diagnostic information—perfect for precision gantry operations.

Responsive Performance

Quad-core CPU ensures smooth, lag-free operation for real-time position monitoring, coordinated axis control, and command execution across your gantry system.

Flexible Connectivity

Multiple connection options including 2x USB ports, RJ45 Ethernet, WiFi, and Bluetooth. Integrates with your existing network infrastructure however works best for your facility.

Standard Functionality Includes

- Home position and axis referencing controls

- Multi-axis coordinated motion

- Individual axis jogging and positioning

- Program selection and execution

- Real-time position feedback

- System diagnostics and status monitoring

- Emergency stop integration

- Customizable operator control layer

Custom Enhancements Available

Extend beyond standard gantry controls with advanced customizations including:

- Application-specific automation sequences

- Advanced multi-point positioning systems

- Production data visualization and reporting

- Integration with conveyors and fixtures

- MES/ERP system connectivity

- Custom alarm management and notifications

Contact us for a custom programming quote.

Typical Delivery Time: 3 Weeks